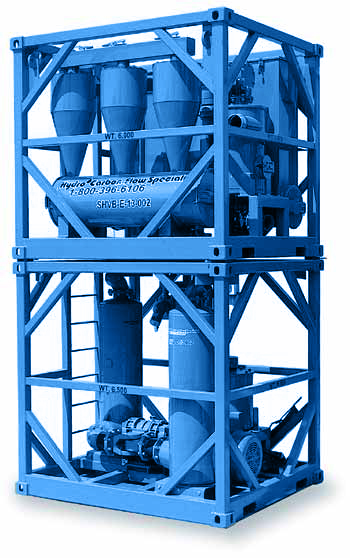

Our most powerful vacuum unit features a Hibon 200 HP unit coupling 3200 CFM flow with the safety of non-sparking construction and a typical operating temperature of 160°F. The system was developed with GapVax, a leading manufacturer and service provider for vacuum equipment.

Since 1992 Hydro Carbon used small non-sparking vane pumps for vacuum services in our zero discharge installations because the Code of Federal Regulations requires non-sparking blowers where gases may be present. Now Hydro Carbon has developed a non-sparking hi-vac unit that runs at lower temperatures, ideal for collecting drill cuttings and solids from drilling fluids. Our hi-vac units maximize your drilling time, minimize maintenance and lower your risk in the presence of explosive gases.

Our new vacuum units are the most advanced in the industry. All units, diesel or electric, feature bronze impellers for spark resistance, a ductile iron casing pressure tested to 150 Psig and the added safety of low-temperature operation.

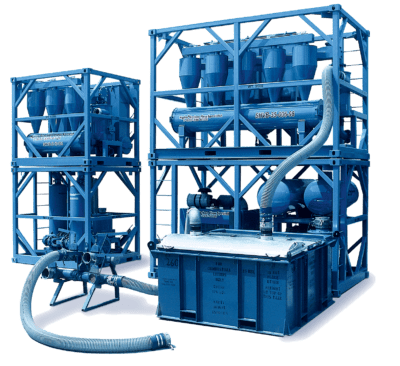

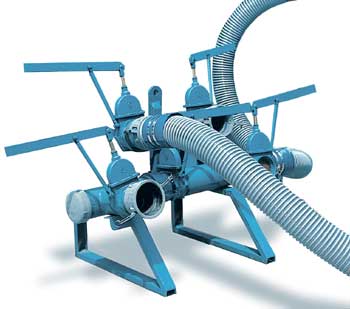

These units are plumbed off the shakers for collection into a Hydro Carbon cuttings box or installed in a central vacuum system that meets all regulatory standards for Class 1, Division 1 operation.