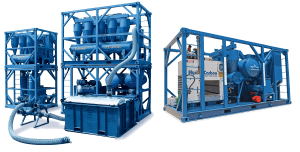

Zero Discharge Systems

Hydro Carbon offers a complete range of customized zero discharge systems designed to meet the oil and gas industry’s needs. We provide everything for complete zero discharge systems, from drill floor to the workboat.

In zero discharge applications our powerful vacuum units maximize your drilling time. The power of Hydro Carbon’s hi-vac units also reduces the need to liquify cuttings. This reduces disposal costs because boxes contain more cuttings and less water.

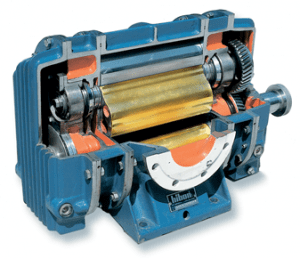

About Hibon Non-Sparking Hi-Vac Blowers

Our vacuum units are the only hi-vac systems with Hibon SIAV positive displacement blowers featuring non-sparking bronze impellers.

- Self-cooling and designed for continuous industrial use, 24 hours a day.

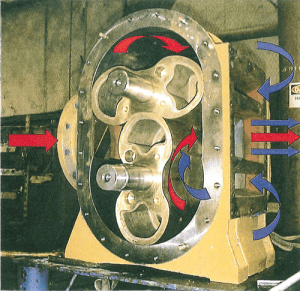

- Figure eight bronze lobes are cooled by natural aspiration through dual cooling ports, so our units run cooler, even under high vacuum. In typical applications, our vacuum units run only 70 to 90 degrees above ambient temperature, nearly 100 degrees cooler than competing positive displacement blowers. Lower operating temperature reduces wear and increases reliability and safety.

- The Hibon SIAV uses durable piston ring seals instead of inferior lip seals, which are more likely to deteriorate and fail.

- Helical timing gears offer more precise timing and reduced backlash. A superior bearing layout provides greater torque relief and a unique one-piece shaft increases reliability.

- Superior engineering, compared with competing vacuum technology such as liquid ring pumps, results in a small, efficient and simple unit with no need for intensive maintenance.