Bottom discharge

Hydro Carbon tanks are ABS certified for bottom discharge. Models reconfigured for bottom discharge have received a D.O.T. exception for transport of corrosive liquids—including formic acid, hydrochloric acid or hydrofluoric (not more than 60% strength) acid.

Our IM101 Tanks are ABS certified for Bottom discharge .

Polyethylene lining

Our hi-bond polyethylene internal lining offers unparalleled resistance to a wide variety of chemicals including salts, solvents, corrosives and caustics.

Stackable and crash resistant

Our IM101’s Finite Element Analysis-based structure is engineered to support the vessel’s maximum gross weight (30,000 lbs.) and offer superior crash protection.

Approved for hazardous materials

These vessels are authorized for transportation of T code hazard material [per CFR Title 49, Part 172.102(c)(7)(i) for 6 bar minimum test pressure with bottom discharge. T1, T2, T7, T8, T11, T13, T14, T16, T17, T20, T22, T23].

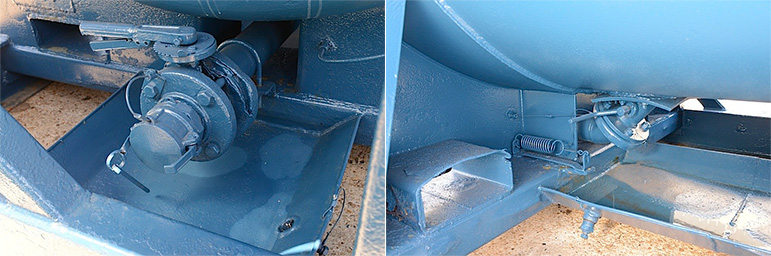

Quick emergency shutdown on every IM101 Tank.

Due in part to our valve location, our tanks are ABS certified to 58 Psig design pressure, 87 Psig hydrostatic test pressure. For bottom discharge applications, three serially-mounted closures—including a Betts internal shutoff valve with emergency remote closure—insures maximum safety and dependability.

A full-length fiberglass platform offers safe access to valves and the 18″ manway. Our hi-bond polyethylene lining covers all internal surfaces exposed to the vessel’s contents, including the manway neck and flanges. Our three-part zinc, epoxy and polyurethane exterior paint offers superior corrosion resistance and less maintenance.

Full-length fiberglass platform offers safe access to vales & 18″ manway.